Laboratory for Flow Control-Fluid mechanics experiment for science & technology-

Ultrasonic measurement

We can understand the flow of a transparent fluid such as water that transmits visible light by the optical visualization. A lot of the fluids around us, however, are opaque fluids (e.g., liquid metal), transparent fluids turbid by containing many dispersions (e.g., emulsions), and liquids in opaque containers (e.g., pipeline). It is hard to perform the optical visualization to them. In such cases, the ultrasound possible to travel through optically opaque media is a useful tool for the measurement. Ultrasonic waves travel through a medium with a constant speed, and they are reflected and transmitted with a constant rate at the interface between substances. This reflected wave and transmitted wave contain information about the material, shape, and velocity of the substances, and it is possible obtain the information by analyzing their waveforms.

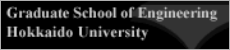

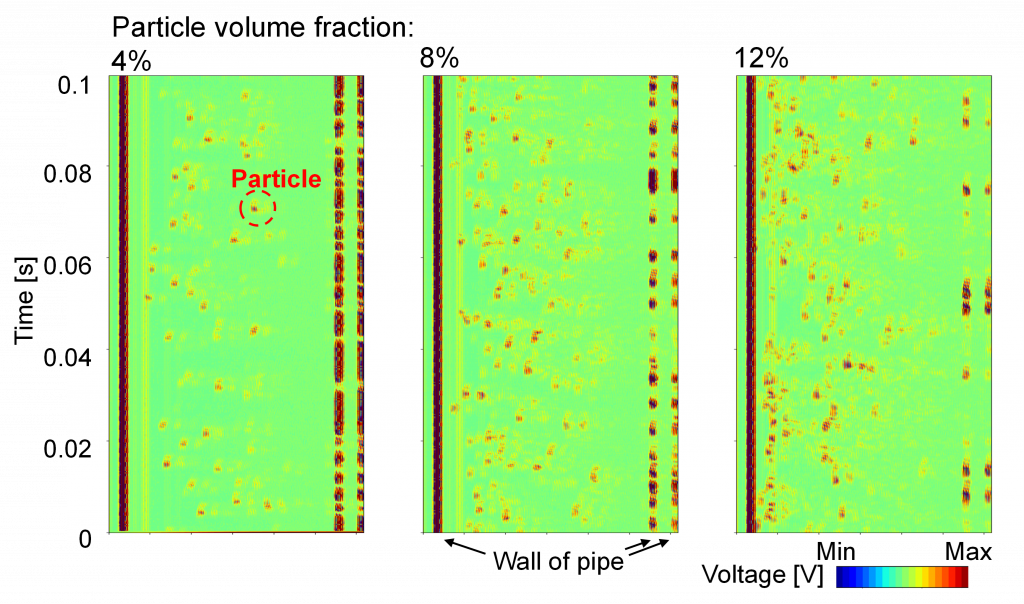

Ultrasonic Pulse Echography, UPE

Ultrasonic pulse echography is a familiar technology for us, which is known as echocardiography and ultrasonography in the hospital. But it is not generally used to measure flows in the industrial field. It makes the measurement be difficult due to a large difference in speeds of sound between medias in the flow, a high speed of the flow, and a high attenuation rate in the media. We have developed new echography techniques for monitoring multiphase flows. In the multiphase flow, ultrasonic waves reflect at the interface where the phase changes. By extracting and analyzing the waveform of this reflected wave, we can measure and monitor various information of the multiphase such as “liquid film thickness”, “distribution of distributed medias”, and “distribution size and concentration of mixtures”.

- Park et al., Ultrasonic pulse echography for bubbles traveling in the proximity of a wall, Meas. Sci. Technol., Vol. 26, 125301 (2015)

- Park et al., Bubbly drag reduction investigated by time-resolved ultrasonic pulse echography for liquid films creeping inside a turbulent boundary layer, Exp. Therm. Fluid Sci., Vol. 103, pp. 66–77 (2019)

- Park et al., Monitoring of Void Fraction and Bubble Size in Narrow-channel Bubbly-flows using Ultrasonic Pulses with A Super Bubble-resonant Frequency, IEEE Sensors J., Vol 21, pp. 273–283 (2021)

- Park et al., Gas volume estimation in a vertical pipe flow considering the bubble size obtained from an ultrasonic velocity vector profiler, Exp. Fluids, Vol. 63, 130 (2022)

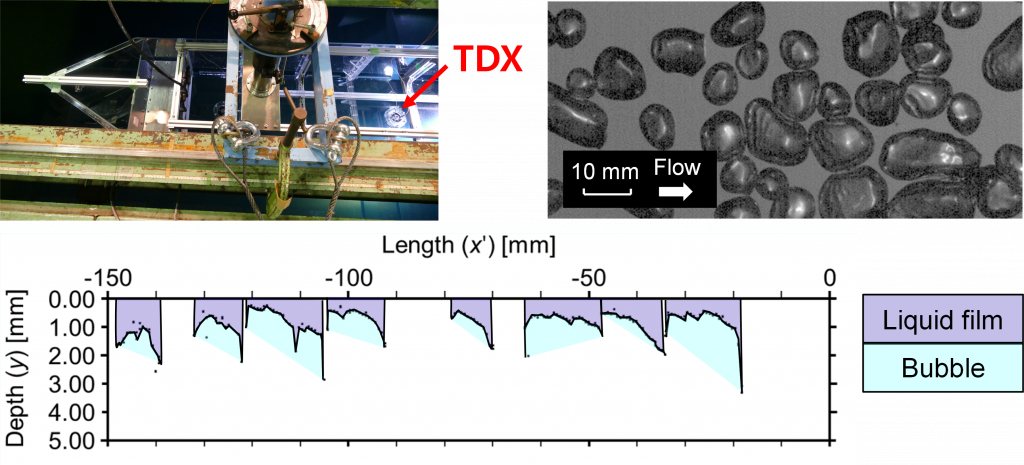

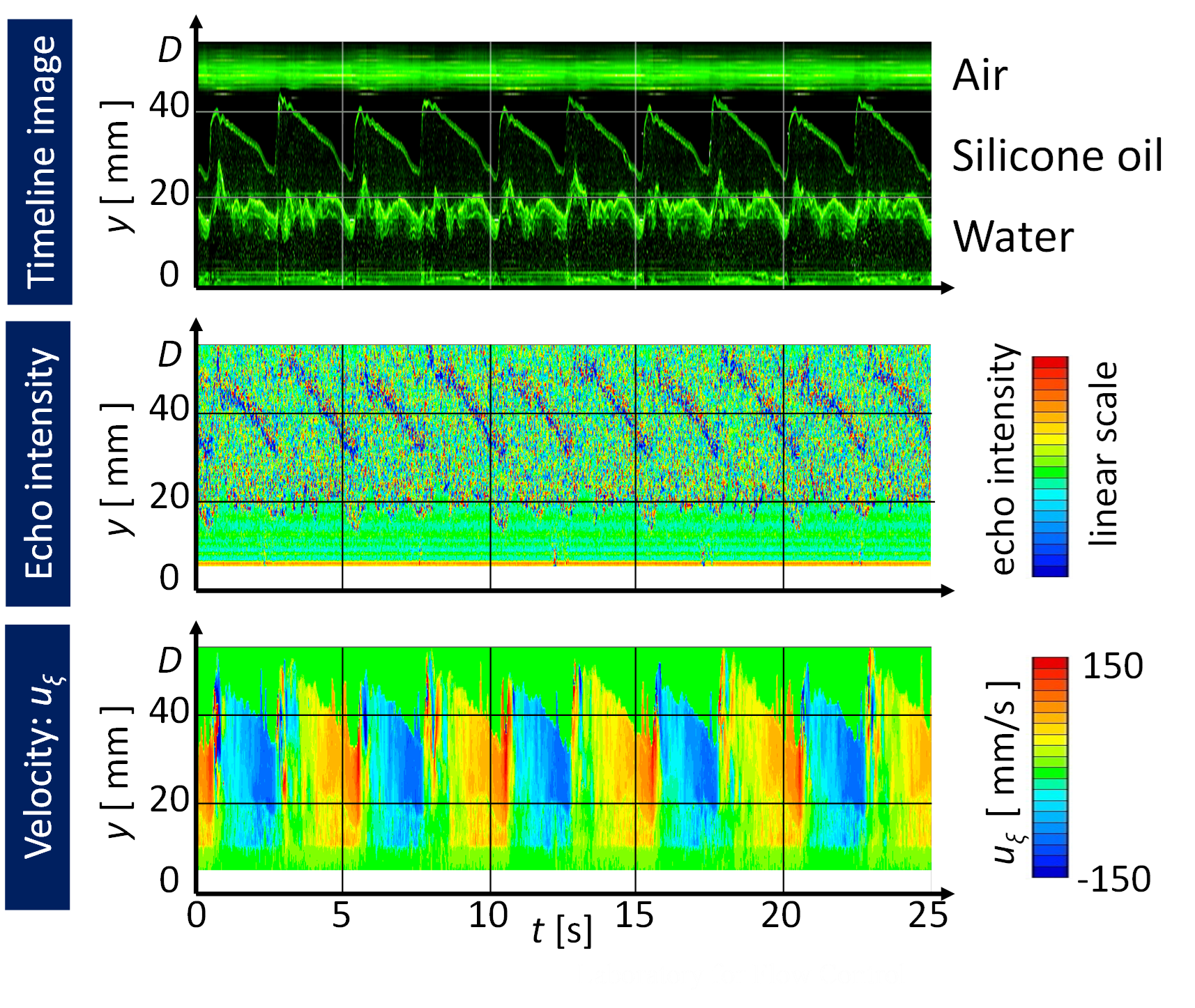

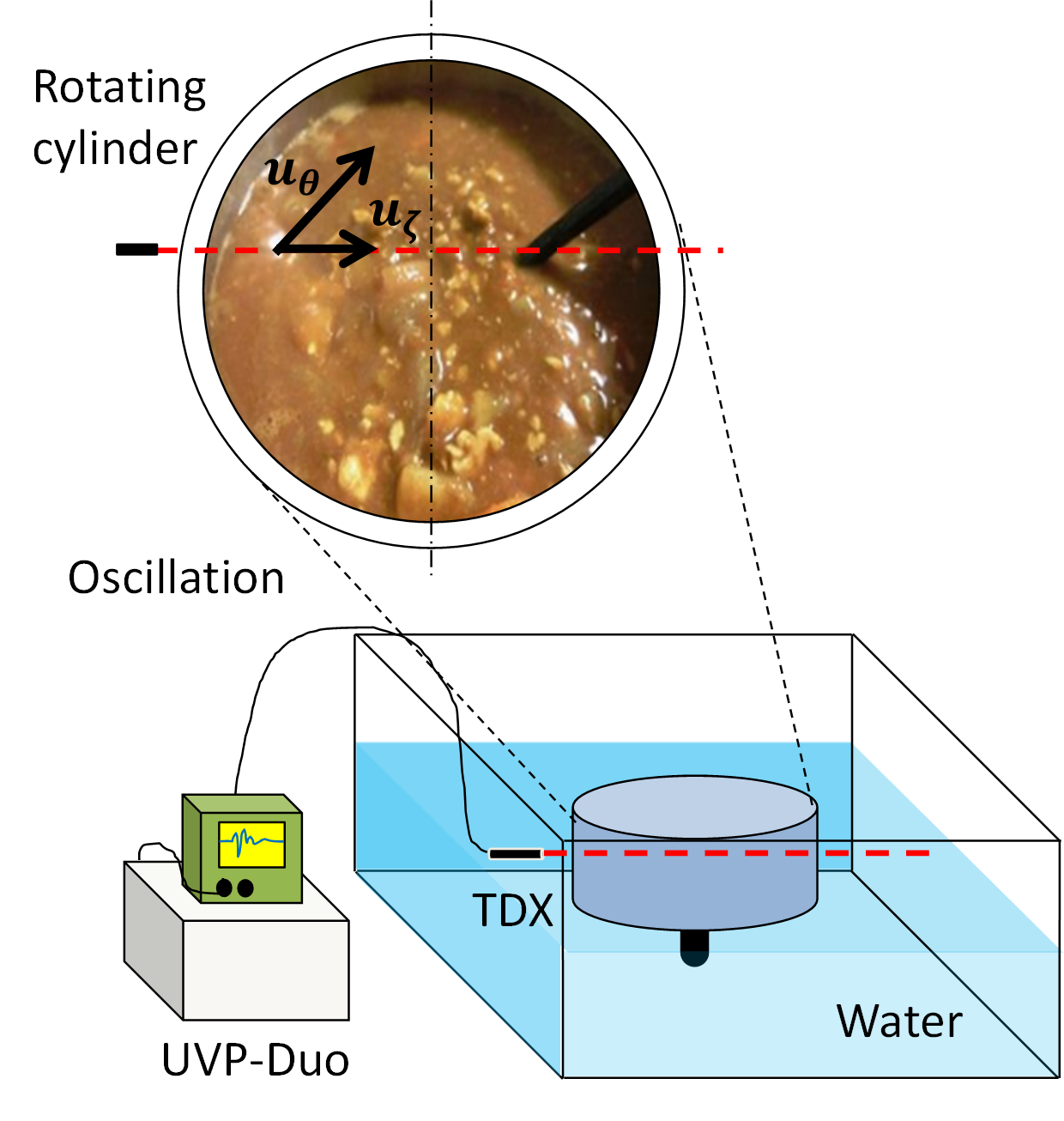

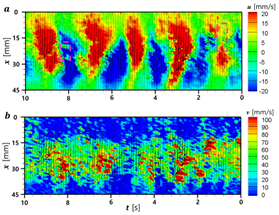

Ultrasonic Velocity Profiler, UVP

When ultrasonic pulses are irradiated into the fluid containing tracer particles, we can receive reflected waves from the particles. Since this reflected wave includes the Doppler effect according to the velocity of the particle in the direction of ultrasonic irradiation, the velocity can be measured by wave detection of the reflected wave. The ultrasonic velocity profiler, UVP, uses this principle to measure the one-dimensional velocity distribution of a fluid along an ultrasonic pulse irradiation line. We are mainly working on three researches using UVP; (1) research on opaque fluids (e.g., liquid metal), (2) functional extension of UVP (e.g., multiphase flowmeters and rheology evaluation) and (3) Development of UVP (e.g., Vector-UVP that can measure multidimensional velocity components)

- Hitomi et al., Ultrasound Flow-Monitoring and Flow-Metering of Air–Oil–Water Three-Layer Pipe Flows, IEEE Access, Vol. 5, pp. 15021–5029 (2017)

- Yoshida et al., Rheological evaluation of complex fluids using ultrasonic spinning rheometry in an open container, J. Rheol., Vol. 61, pp. 537–549 (2017)

- Yoshida et al., Rheological properties of montmorillonite dispersions in dilute NaCl concentration investigated by ultrasonic spinning rheometry, Appl. Clay Sci., Vol. 161, pp. 513–523 (2018)

- Hitomi et al., Measurement of the inner structure of turbidity currents by ultrasound velocity profiling, Int. J. Multiphase Flow, Vol. 136, 103540 (2021)

- Yoon et al., Development of an instantaneous velocity-vector-profile method using conventional ultrasonic transducers, Meas. Sci. Technol., Vol 33, 035301 (2022)

- Murai et al., Ultrasound Doppler measurement of air-lift two-phase and particulate three-phase pipe flows, Exp. Fluids, Vol. 63, 126 (2022)