Laboratory for Flow Control-Fluid mechanics experiment for science & technology-

Ship drag reduction

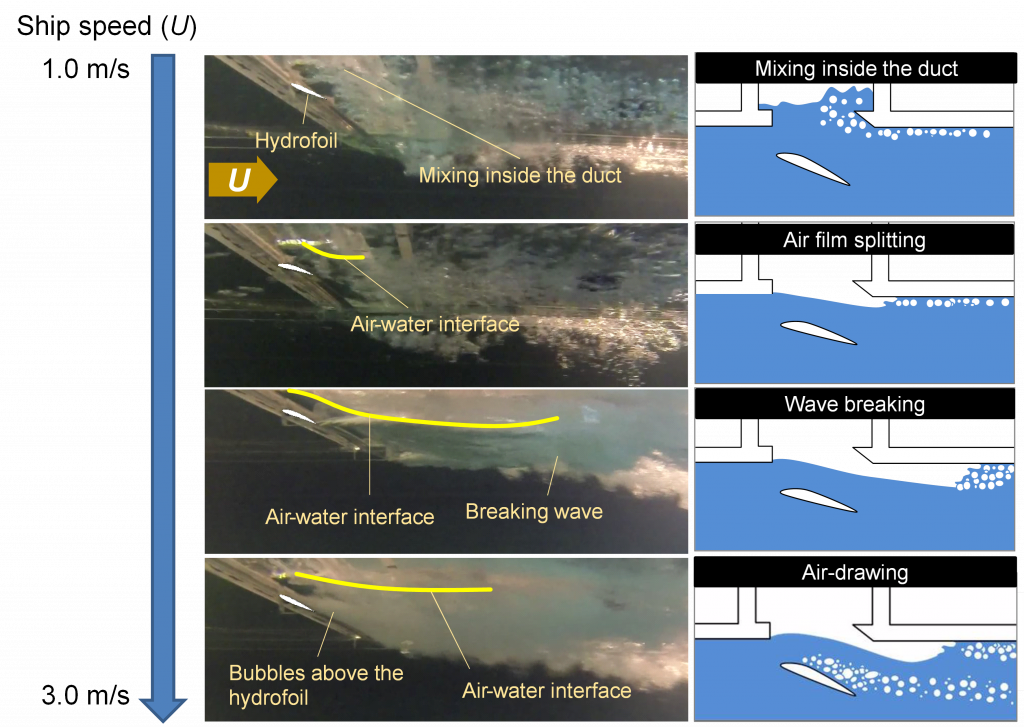

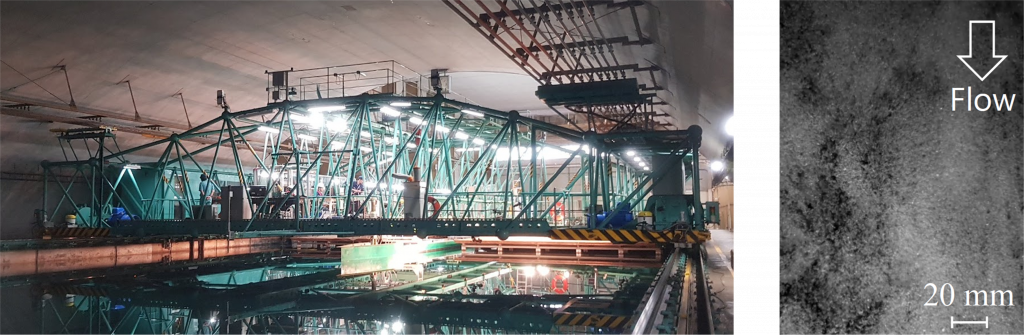

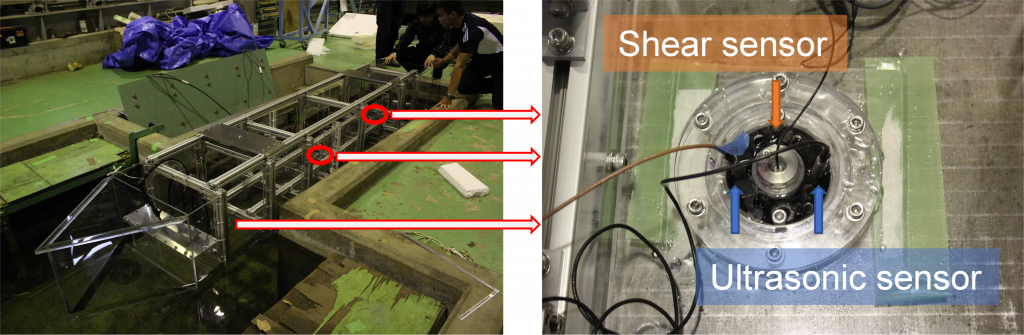

Japan, one of the shipping and shipbuilding superpowers, has launched the “International Shipping GHG Zero Emission” project to eliminate greenhouse gas emissions by 2028. To achieve this goal, it is essential to develop frictional drag reduction technology that has been neglected due to its high technical difficulty. About 70% of the power is consumed to overcome the frictional drag generated on the hull surface in the case of a large commercial ship with a slow voyage speed. We have been researching an air lubrication method possible to reduce the frictional drag on the wall by up to 80% by injecting bubbles into the turbulent boundary layer. This research has been carried out in collaboration with various shipping and shipbuilding companies and the National Maritime Research Institute in Japan. Our primary research topics for air lubrication are understanding the mechanism of frictional drag reduction, construction of a monitoring system to measure the bubbly flow beneath the ship bottom, and development of a control method of the bubbly flow to improve the efficiency of the drag reduction.